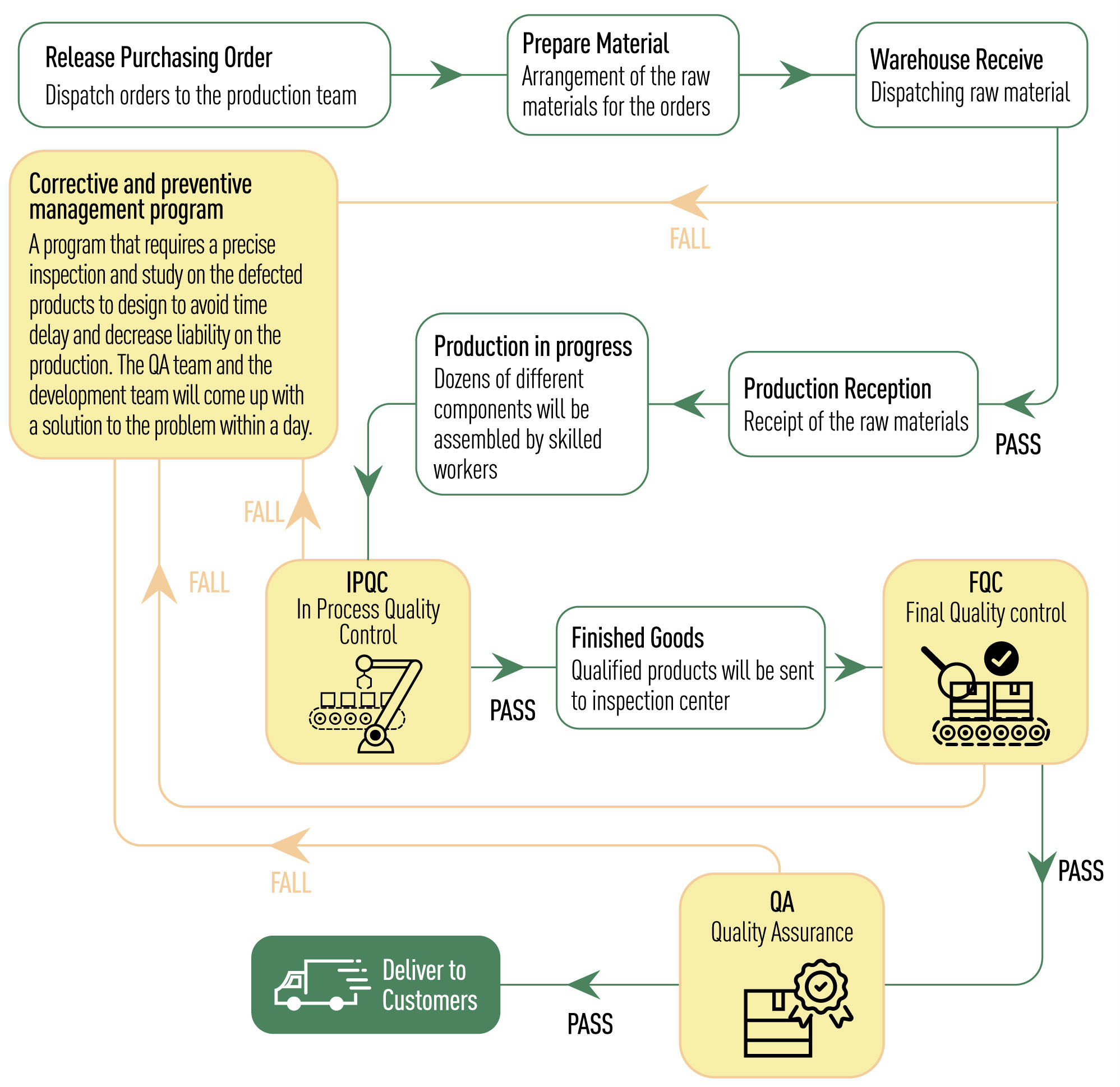

How Quality is Controlled?

In order to ensure stability and reliability, MACHINABIS has been fully committed to the overall quality improvement business from the very beginning. The quality indicators have been integrated into our product quality and service processes. The specific quality management system monitors all products and processes to ensure that The quality is consistent. Our goal is to deliver quality products that meet our customers’ needs through continuous quality corrections. Through a series of tests and strict quality control procedures, ISO-9001 quality management certification must also be followed to ensure the highest quality based on the necessary control processes.

What tests we do in each order?

- Visual inspection

- Vibration test

- Short circuit protection test

- Smoking timeout protection test

- Battery low voltage protection test

- Overload protection test

- Working voltage detection

- Maximum output current detection

- Static power consumption detection

- Heating wire resistance detection

- Output voltage detection

- Output mode detection

- Suction display detection

- High temperature storage test

- Low temperature storage test

- Negative pressure test

- High and low temperature environment testing

- Oral Count Test

- Leakproofness test

- Draw resistance test

- Sensitivity test

- Pull test

- USB plug and unplug test

- Drop test

- Surface temperature test

- Airtightness test

- Acid and alkali resistance test

- Salt spray test

- Alcohol wear test

- Artificial sweat test

- Cosmetic resistance test

- Vape oil resistance test

- Vape experience test